OTHALA RT packaging machines

Viable, reliable, performing, the heritage you leave behind!

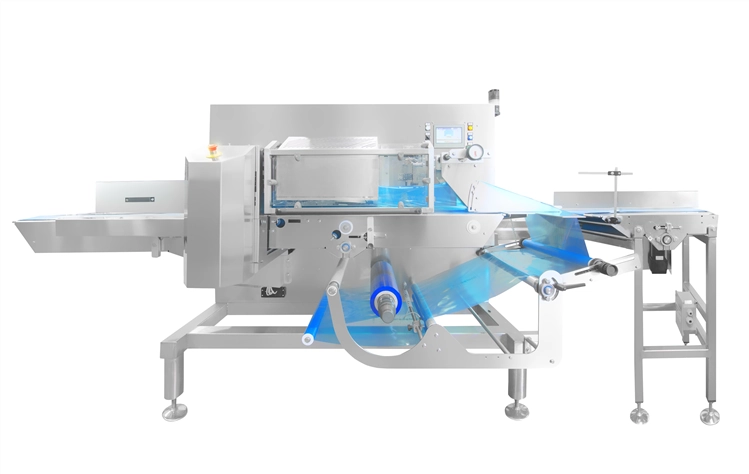

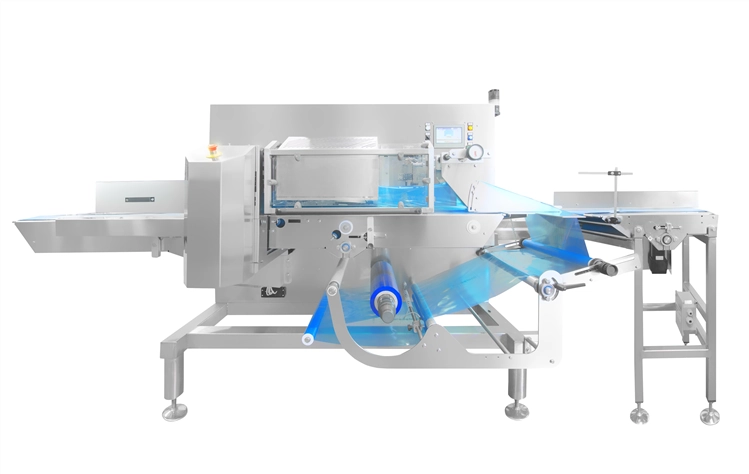

OTHALA RT is the Rotary Top Seal version of our HFFS packaging machines with the film reel in the lower part of the machine and longitudinal welding in the upper part of the pack, perfect for products that are difficult to transport, as it allows the product to enter the machine already resting on the film. Built on a cantilevered structure, and easily accessible from the operator performing daily packaging routine.

The drive mechanisms are positioned separate from the packaging process. This design concept prevents processing and product residues from ending up in the drive mechanisms. This reduces cleaning times, improves the life of the components, and guarantees the best hygienic conditions and easy access for maintenance.

The robustness, ease of handling, reliability, versatility, and flexibility ensure perfect adaptability of the machine to the packaging needs in each application.

Sophisticated, but easy to use electronics, manages all the functions of the machine via an external touch screen interface. The product feeding takes place through a conveyor belt, already supplied with the machine.

The Othala can be integrated with any automatic loading equipment, to reach very high production results. The machine is manufactured in compliance with current CE Machinery Directive and for the use in food handling environments.

Main characteristics

- Left version (products flows from right to left).

- AISI304 stainless steel cantilevered structure.

- 7” Colour Touch Screen interface

- Single, air-expansion, reel holder

- 520mm maximum reel width

- 1000mm integrated feeding conveyor with controlled product handling

- 3 pairs of welding wheels (1 cold for film pulling, 1 hot for film welding, 1 for film folding)

- Automatic opening of the welding wheels at machine stop

- Integrated output conveyor equipped with a belt food contact compliant.

- Stainless steel adjustable film former

- Rotary cutting and sealing unit

- Safety guards in transparent polycarbonate, openable and equipped with safety sensors.

- Printer signal ready manageable from the touch screen and storable to create a recipe program

- Electronics located inside the machine frame, easily accessible and protected from humidity and infiltrations.

- Power supply: 3 phase 400 + Neutral + Ground - 50Hz

Main optionals

- Right version

- Eurohole

- Pre-heating system

- PE film welding system

- Trimming of excess film

- Micrometric dosing of liquids (alcohol, anti-mold)

- Gas insufflation

- Gas analyzer

- Batch, code, date printer / labeller

- No product – no bag

- Automatic rejection of non-complaint packages

- “Non in phase” function

- Registered wrap to automatically adjust the length of the package.

- Automatic feeding systems.

- Frame on wheels

- Teleservice device

Gallery

Show others images

Packable products

Show others Packable products