The disposable food trays used on production lines must be stored in an orderly fashion in order to occupy a minimal amount of space, but must also be easily separated. The possibility for the trays to be quickly and easily de-stacked on the belt conveyors, repeatedly and without any errors, is an extremely important factor for the efficient and cost-effective functionality of any company.

Combined with an efficient tray design, these easy-to-install, stand alone machines are capable of handling extremely high product volumes (much greater than those that can be handled by an operator). In addition to increasing the loading potential, de-stackers can also be used in situations considered to be dangerous for the operator, and in cases where the operator is likely to suffer repeated strain injuries (RSIs).

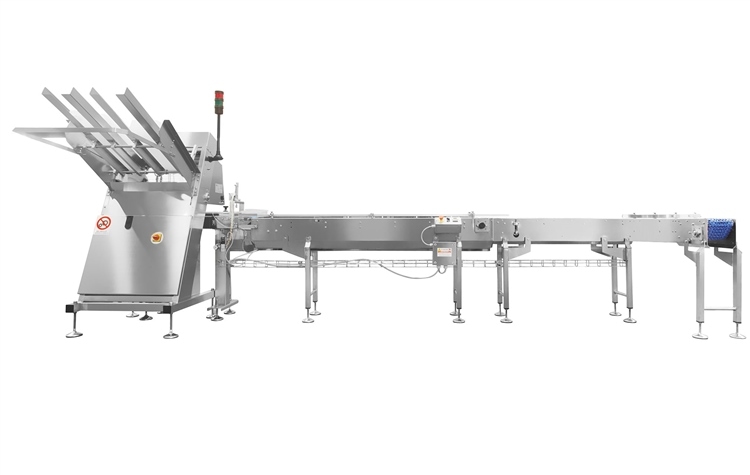

Thanks to its compactness, ease of use, and minimal maintenance requirements, the machine can be easily installed on any industrial line.

The machine’s shape is designed to make it easy for the operator to load the stacks of containers. All the components are made from sanitisable and washable materials.

The machine can be equipped with stepper or continuous belt conveyors upon request: the electrical panel is built in.

The machine is manufactured in compliance with the current CE standards, the Machinery Directive, and the regulations for use in food handling environments.