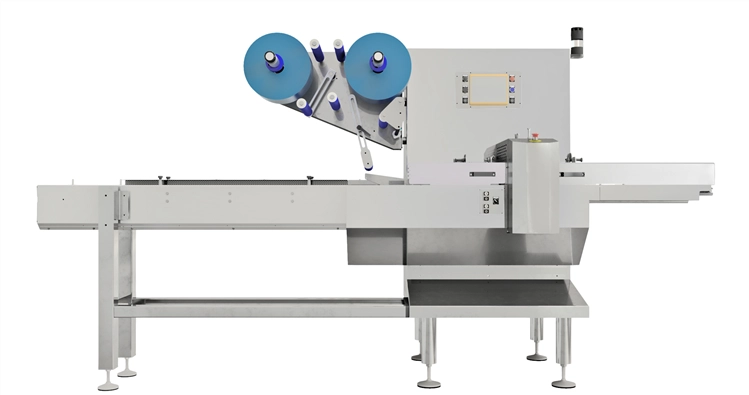

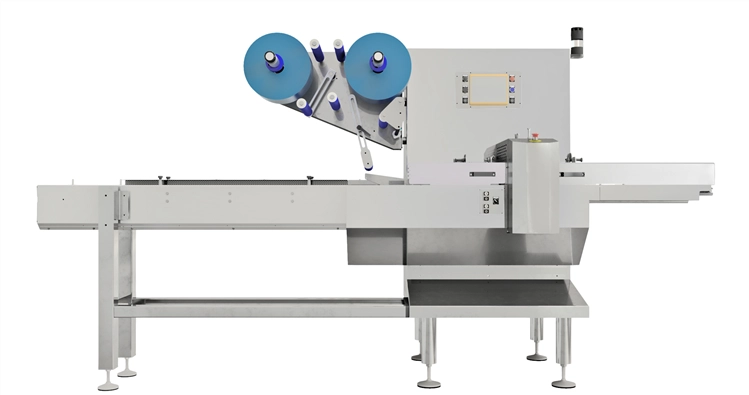

GEBO packaging machine

Compact design, ease of use, small efforts for excellent packaging results!

The “smallest of the family” GEBO packaging machine, is an electronic machine with 3 stepless servo motors run by intelligent driver motion controller.

Ideal for small, medium production, it is designed to meet the needs of both food and non-food industries. This packaging machine, with a rotary “cut and seal” system, is equipped with a latest generation PLC for temperature control, integrated diagnostic, different format memorization (recipes), and a multilingual, multifunction touch screen display.

The structure, made entirely of stainless steel, allows it to be easily placeable in food, medical and humid environments. The electronics are located inside the machine’s frame, easily accessible but protected against moisture and infiltration. Various accessories can be added to the basic model.

The machine is manufactured in compliance with current CE Machinery Directive and for the use in food handling environments.

- Electronics and motorization: CMZ

- Gearboxes: MOTOVARIO

- Pneumatics: FESTO / CAMOZZI

- Inverter: PARKER

- Operator Terminal: CMZ 7”

- Sensors: SICK / PIZZATO

- Belts: AMMERAAL

- Support feet: NGI

Main technical features

- Left/right version (products flows from the right to the left)

- AISI 304 stainless steel cantilevered structure

- 7” Colour Touch Screen interface

- Rotary cutting and sealing unit

- Average packaging speed: 100 packets/minute

- 2000 mm integrated manual loading conveyor

- 3 pairs of welding wheels (1 cold for film pulling, 1 hot for film welding, 1 for film folding)

- Single shaft film reel holder, with manual centring, fastening system

- 420mm maximum reel width

- Automatic opening of the welding wheels at machine stop

- Stainless steel fixed film former

- 800mm integrated output conveyor equipped with a belt food contact compliant.

- Safety guards in transparent polycarbonate, openable and equipped with safety sensors.

- Printer signal ready manageable from the touch screen and storable to create a recipe program

- Electronics located inside the machine frame, easily accessible and protected from humidity and infiltrations.

- Power supply: 3 phase 400 + Neutral + Ground - 50Hz

Main optionals

- Eurohole

- Micrometric dosing of liquids (alcohol, anti-mold)

- Gas insufflation

- Batch, code, date printer / labeller

- Automatic feeding systems.

- Double shaft film reel holder

- Registered wrap to automatically adjust the length of the package

- Adjustable film former

- No product – No bag function

- Gusset packaging

- Removal of excessive air from package

- Frame on wheels

- Teleservice device

Gallery

Show others images

Packable products

Show others Packable products