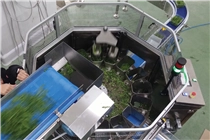

JERA TT packaging machine

Revolutionary elegance for perfect packaging!

Technology at the service of the most demanding packaging! JERA TT is the result of experience gained over time.

It is a fully electronic packaging machine particularly suitable for MAP packaging thanks to the Box Motion transversal sealing unit which allows to obtain hermetically sealed packages.

It is also suitable for the use of thick film and for the packaging of products with micrometric dosage of liquids (alcohol, anti-mold).

The integration of printing and dialogue systems, upstream and downstream integrated systems, ease, and intuitiveness of use, make this packaging machine the best solution for food and non-food companies that require quality and performance standards of absolute excellence.

The packaging machine JERA TT is equipped with top quality components for constant production efficiency over time and an excellent result of the final packaging:

- Electronics and motorization: OMRON / CMZ

- Gearboxes: WITTENSTEIN / MOTOVARIO

- Drum motors: RULMECA

- Pneumatics: FESTO / SMC / CAMOZZI

- Inverter: OMRON / PARKER

- Operator Terminal: EXOR 7 " /CMZ 7”

- Sensors: SICK / PIZZATO

- Belts: AMMERAAL BELTECH

- Supporting feet: NGI

Main technical features

- Right version

- Structure in AISI 304 stainless steel

- 7” multilingual colour touch screen interface

- Built-in loading conveyor, with automatic product management.

- New welding wheel heating system that allows reduced energy consumption and accurate temperature control.

- Film pulling and sealing by means of three pairs of wheels (1 cold for film pulling, 1 hot for film welding, 1 for film folding), the pair of cold rollers can be tilted to obtain a perfect adherence of the film.

- The transversal sealing system is Box Motion, thus realizing short and long packs without penalizing production. Welding jaws with a special profile that allows to obtain hermetic sealings, and a greater product passage.

- The infeed and outfeed conveyors of the sealing system are equipped with sealed edges belts, food contact compliant.

- Motorized expansion reel holder shaft, reel centring and compensation brake. 600mm maximum reel width

- Photocell for print centering

- Pneumatic pad for the removal of excess air, to avoid the bloating effect

- Lexan protections, with natural anodized aluminium frame, openable and equipped with safety sensors

- Teleservice

- Standard speed 60pcs / minute

- Power supply: 3 phase 400 + Neutral - 50Hz

- Consumption: 14 Amp - 6 Bar (continuously)

Main optionals

- Left version

- Eurohole

- Loading conveyor for the manual handling of the product

- "No product - No bag" function

- Micrometric dosage of liquids (alcohol, anti-mold)

- Gas insufflation system (MAP)

- Gas analyzer

- Double film feeding with automatic reel change

- Automatic rejection of non-compliant products

- Frame on wheels

- Printer / Labeller

DIMENSIONS: 4500mm x 1200mm H 1600mm

WEIGHT: 800Kg

Gallery

Show others images

Packable products

Show others Packable products