GALA flowpack packaging machine

Simple, versatile, and reliable!

The GALA packaging machine is an electronic machine equipped with 4 axes servo-controlled by intelligent drivers. It’s capable of packaging a wide range of both food and technical products, and is ideal for packaging crackers, biscuits, wafers, chocolate bars, cereal bars, snacks, bread, pizza, trays, gadgets, stickers, etc. The Gala model is a technologically advanced Flowpack machine with rotary sealers. It's reliable, easy to use and to maintain, which makes it an excellent ally for medium/high production volumes. It comes equipped with a state of the art PLC with temperature control, integrated diagnostics, a memory record for different formats, and a multifunction and multilingual touch screen display. The structure, entirely built in stainless steel, allows this machine to be easily used in damp environments; the electronics are located inside the machine’s frame, where they can be easily accessed and are protected against humidity and infiltrations. Various accessories can be added to the basic machine model. The machine is manufactured in compliance with the current CE standards and the regulations for use in food handling environments.

Main technical characteristics

- Right/left version

- Cantilevered structure in AISI 304 stainless steel with rounded corners

- Colour touch screen interface

- Rotary cutting/sealing functionality

- Packaging speed: 30m sealed/min

- Incorporated loader, with product-controlled operation

- 4 pairs of sealing wheels (1 cold for film feeding, 2 heated for sealing, 1 for folding flaps)

- Single shaft reel holder

- Mould centring sensor

- Possibility of cold sealing the packages

- Fixed stainless steel forming tunnel

- Output belt in FDA GRADE material, with independent motorisation

- Openable Lexan guards with safety sensors

- Suctioning of the air in the package

- Predisposition for marking and labelling devices

- Compatible films: all heat-sealable and machinable films, such as polypropylene, lightweight coupled film, cold sealing.

Types of packages

- Standard pillow bags

- Pillow bags with lateral sealing

- Pillow bags with Euroslot

- Pillow bags with zip closure

- Gusseted bags

- Gusseted bags with lateral sealing

- Gusseted bags with zip closure

- Easy Open gusseted bags

- Easy Open gusseted bags with Euroslot

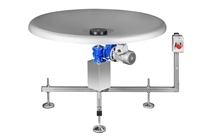

Optionals

- Gas blower nozzle

- Micrometric liquid dosing (alcohol, anti-mould)

- Double reel support

- Double reel support with semi-automatic on-the-fly reel-changing system with no need to decrease the machine’s speed.

- Expanding reel support

- Reel support Useful length 700 diameter 380

- Stainless steel roller conveyor

- Universal forming tunnel

- No product, no bag function

- Moulding unit

- Lateral blower for gusseted bags

- Interior machine air conditioner

- Euroslot

- Machine base on wheels

- Treatment of the aluminium parts with a non-stick and corrosion resistant nanotechnological FDA ceramic coating (EVO CPC), which also provides for a long-lasting self-cleaning effect and reduces maintenance costs

- Treatment of the stainless steel with a nanotechnological coating (EVO G&S), for greater wear resistance and stain protection. It protects against water, oil, acids, moisture, mould, etc., while at the same time providing for a long-lasting self-cleaning effect and reducing maintenance costs.

- Remote support. The router allows for the parameters to be checked, operating faults to be identified, and interventions to be performed remotely.

AVAILABLE MODELS

- Gala Monodose: suitable for packaging small products and for use in environments with limited space.

- Gala LD MAP: equipped with a Long Dwell cutting/sealing unit for high-speed processing and air-tight package sealing. Inner gas blower nozzle.

- Gala SAN: sanitisable version. Structure and parts in contact with the product in stainless steel, and product loading output belt with quick release function to facilitate belt cleaning and replacement. Aluminium parts treated with a nanotechnological ceramic coating (EVO CPC).

Technical data sheet

Standard machine:

- 7" touch screen interface Ethernet port + USB PT070-WST4B-F1R1

- Weight 800kg

- Cutting/sealing functionality with rotary sealers. Maximum rotation & 220mm, maximum sealer dimensions 350mmx32mm thick. Motor SD1261/CAN.331- 45-135VDC + drive 450 1800 / motovario gear reducer NMRV050 i=10 – F. &14, flange 120 mm

- Cartridge resistors L350 D 15 220V 700W

- Type J thermocouple probes

- Automatic loader: aluminium structure. Protective panels and lateral guides in stainless steel. Length 1550, FDA GRADE product detachment and advancement materials, equipped with a channel vacuum pump product retention system CL40HS. Motor SD1261/CAN.331- 45-135VDC + drive 450 1800/motovario gear reducer NMRV050 i=10 – F. &14, flange 120 mm. Product presence sensor SICK/Datalogic/Pepperl+Fuchs

- 4 pairs of sealing wheels, one of which is heated by 350W 110V resistors (Omega). Motor SD1261/CAN.331- 45-135VDC + drive 450 1800 / motovario gear reducer NMRV050 i=10

- Automatic heat sealing wheel aperture

- Single shaft reel holder, useful width 600mm, with simple reel replacement system, independent motorisation NMRV040 i=15 + 0.37kw motor

- Fixed forming tunnel in stainless steel

- 1000mm long output belt in FDA GRADE material, with independent motorisation via drum motor mod. 80LP RL 280 EL 286 speed 0.59 m/s IP66

- Openable guards for protecting the product at the input and the output from the cutting/sealing unit, with stainless steel frame and Lexan tunnel, equipped with safety sensor

- Channel vacuum pump mod. CL40HS for removing the excess air from the packages prior to sealing.

- Mould centring sensor SICK/Datalogic/Pepperl+Fuchs

- Electrical power supply: 400 + Neutral – 50Hz

- Consumption: 8 Amp – 6 Bar (continuous)

- Automatic aperture of the sealing wheels

- Standard reel dimensions: Width 600mm, diameter 380mm

- CMZ electronic and motorisation components

- Camozzi pneumatic components

- NGI anti-vibration support feet in stainless steel

Gallery

Show others images

Packable products

Show others Packable products