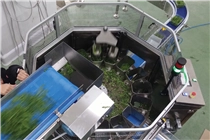

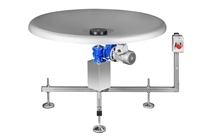

Thanks to its design, efficiency and accuracy, this machine is the ideal solution for filling trays with fresh vegetables, candies, biscuits, and any other product that can be dosed using the multi-head scale. It can be used to fill trays and crates of various shapes and sizes, based on the user’s requirements. Frame, panels and the integrated electrical panel are in stainless steel, to ensure easy cleaning and guarantee proper hygiene conditions. This machine is suitable for damp environments. Various accessories can be added to the basic machine model. The machine is manufactured in compliance with the current CE standards and the regulations for use in food handling environments.

Standard Machine: 16 filling stations